How It Work?

Home Turnkey Plant Comparison & Advantages

How It Work?

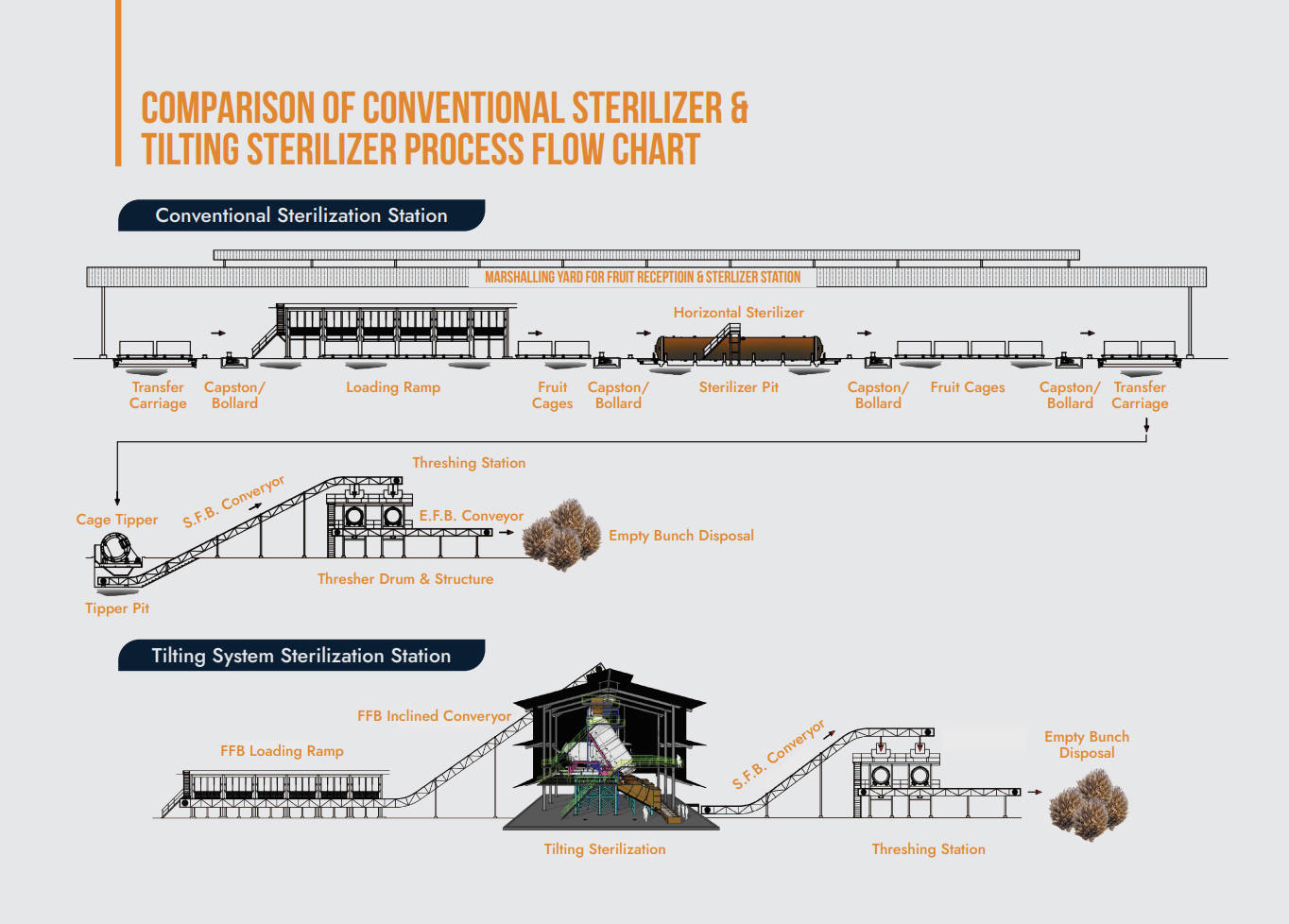

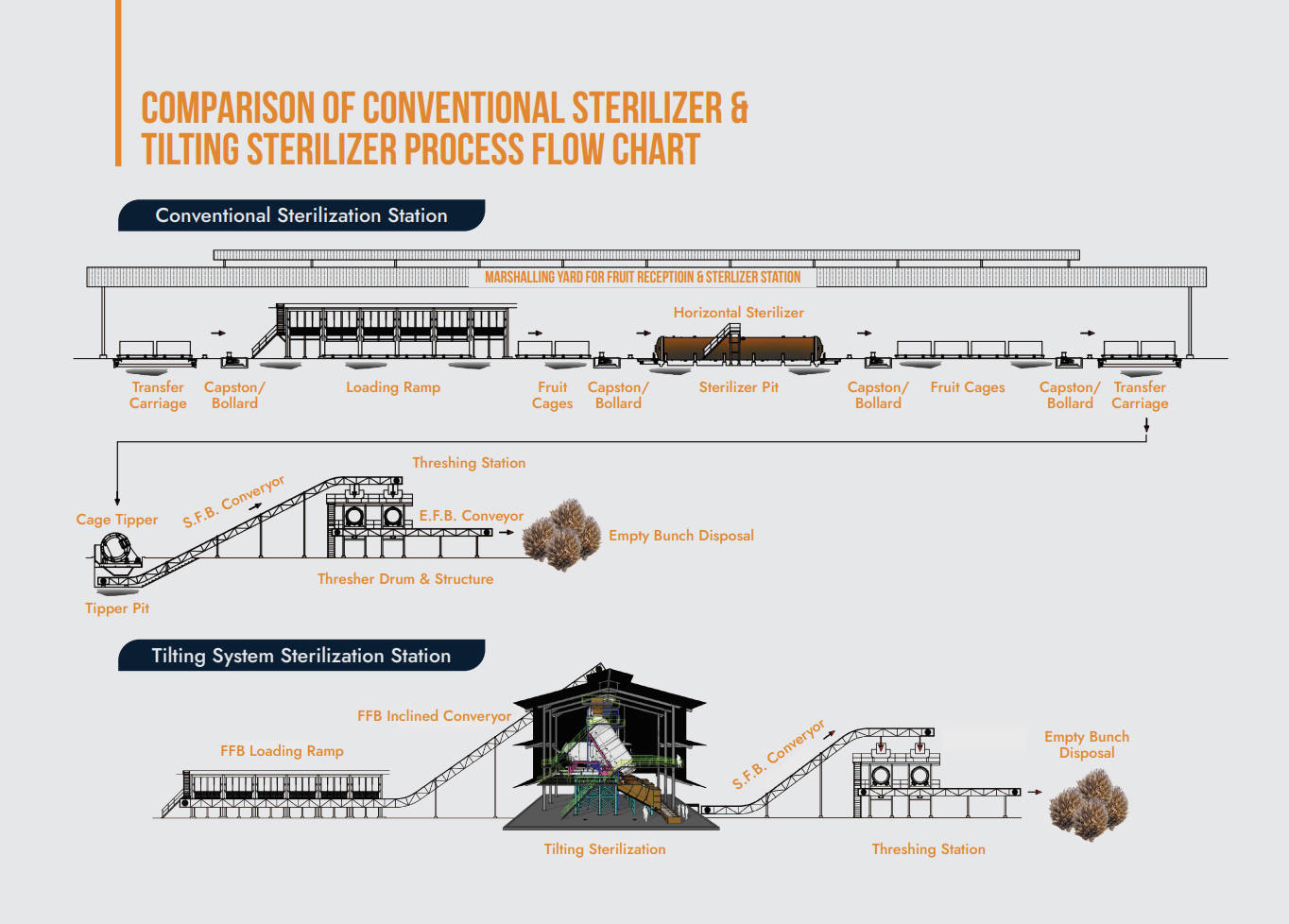

Conventional Sterilizer vs Tilting Sterilizer Process Flow Chart

Space Efficiency: Tilting sterilizer system utilizes only 30% of the space compared to horizontal systems, conserving land and promoting efficient land use.

Reduced Tree Felling: Adoption of this system in new palm oil processing plants significantly decreases the need for tree felling, actively contributing to the preservation of our valuable green spaces.

Eco-Friendly Choice: By minimizing land usage and tree impact, the tilting sterilizer system helps safeguard our environment and supports sustainable practices in palm oil processing.

Swift & Secure Sterilization: The tilting sterilizer offers the quickest and safest method for sterilizing Fresh Fruit Bunches (FFB), ensuring efficiency and safety in the process.

Precise PLC Control: Equipped with precisely engineered PLC control systems, each unit guarantees exceptional reliability, user-friendly operation, and easy maintenance.

Seamless Operation: The control system, working with limit switches and transmittals, ensures seamless functioning of critical systems including steam/condensate management, hydraulic systems, FFB feeding mechanisms, tilting mechanisms, and door operations.

Reduced Steam Usage: The tilting sterilizer system utilizes minimal steam quantities, conserving energy resources and promoting efficiency.

Diminished Waste: By generating reduced wastewater and oil losses, this system minimizes environmental impact, making it an eco-friendly choice.

Conscientious Selection: Choosing the tilting sterilizer system demonstrates a commitment to energy efficiency and environmental responsibility, aligning with sustainable practices.

Lower construction cost with less machineries

High throughput with less steam consumption

Minimum oil loss

Much smaller sterilization station with less heat loss

Lower power consumption and waster water discharge

Easy & safe to operate

Lower operation & maintenance cost

Minimum damage to FFB

Oil in condensate can be recovered separately

| HIGH THROUGHPUT | |

| Sterilization Process | Time(min.) |

| Dearation | 1 |

| 1st Peak | 5.5 |

| 2nd Peak | 0 |

| Holding | 36.5 |

| Exhaust / Purging / Drain | 5 |

| Door Open Interlock Delay | 2 |

| Total Steaming Time | 50 |

| FFB Filling | 15- 18 |

| Discharge SFB | 7 - 15 |

| Total Cycle Time | 73-83 |

Based on steam pressure 40 psig TeeTeh Palm Oil Mill

| TECHNICAL SPECIFICATION | |

| Capacity | ± 30T |

| Throughout Capacity (t/hr) | ± 23T |

| Shell Length (mm) | 7200 |

| Diameter (mm) | 3200 |

| Vessel Volume (m3) | 58 |

| nlet/outlet Door (mm) | 1500 / 1700 |

| Design Pressure (kg/cm2) | 3.5 |

| Design Temperature (c) | 150 |

| Material For Shell Body & Dish Head | Stainless Steel (SA 240 GR.304) |

| Cycle Time | (± 80min) |

| Steam Consumption | 170~200 kg / ton FFB |

± 5.7 ton / cycle

Let`s Connect

Industry Solutions Start With a Simple Contact